CTRA fabrique des réservoirs en fibre de verre (PRFV) pour le stockage de divers produits alimentaires conformément à la norme EN10 / 2011. Idéal pour l’eau potable avec la déclaration d’aptitude alimentaire EU10/2011.

Production

CTRA is fully qualified and proficient in the processing of :

Mastery and quality assurance of thermosetting materials

Resin / Matrix

CTRA processes and masters the following types of resin and has adequate PQR (Procedure Qualification Record):

- Bisphenol A (BPA) resin

- Isophthalic resin

Lining resin

CTRA implements and masters the following corrosion-resistant linings and has the adequate PQR (Procedure Qualification Record).

- Single-layer lining

- Double-layer lining

- Anti-static lining

- Abrasion-resistant lining

Mechanical-strength

CTRA masters the following lamination processes and has the adequate PQR (Procedure Qualification Record):

- Contact molding

- Filament winding

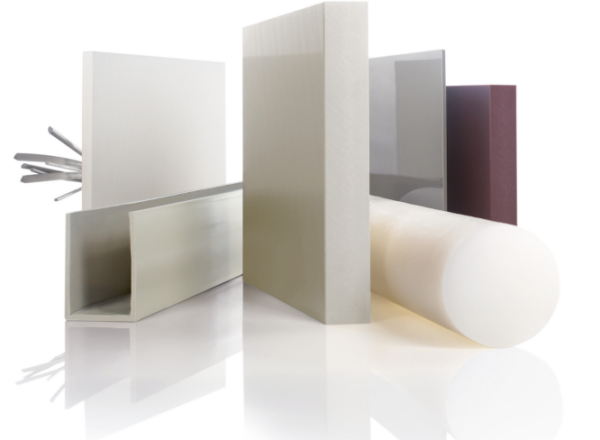

Mastery and quality assurance of thermoplastics

PE : (C2H4)n

Polyethylene is an extremely versatile plastic. This often black-colored and UV-stabilized material is characterized by good corrosion and abrasion resistance.

It is highly resistant to chemicals and boasts excellent processability.

CTRA’s experience will help you determine the best possible choice of thermoplastic.

PP : (C3H6)n

Polypropylene is the most widely used material in chemical-technical applications. It is stiffer than PE, especially in higher operating temperature range (up to +100°C).

It is also characterized by excellent chemical resistance and good durability towards many fluids.

Among the types of polypropylene, Homopolymers (PP-H) and Copolymers (PP-C) are the two main ones:

PP-H consists entirely of a combination of propylene monomers and covers the operating temperature range from 0°C to Ab. +100°C.

AS for PP-C, propylene monomers are chemically combined with ethylene monomers, which increases the resistance on a smooth specimen in cold weather. PP-C covers a temperature range from –20°C to Ab. +80°C and is less rigid than PP-H.

PVC : (C2H3Cl)n

Unlike partially crystalline materials (PE and PP), Polyvinyl Chloride (PVC) is an amorphous thermoplastic, whose operating temperature range is from 0°C to +60°C. It has very good chemical properties, meets the most diverse requirements in terms of flammability and boasts excellent processability.

There is also PVC-C, which is a super-chlorinated PVC. Thanks to its intensified chlorine content, it has a much wider operating temperature range and outstanding chemical resistance, especially to acids. It is therefore very suitable in the chemical process industry. Its operating temperature range is from –40°C to +95°C.

PVDF, ECTFE, PFA

For particularly demanding applications in terms of chemical resistance and operating temperature range, there are various partially or fully fluorinated high performance materials such as Polyvinylidene Fluoride (PVDF), Ethylene Chlorotrifluoroethylene (ECTFE), Fluorinated Ethylene Propylene (FEP) or Perfluoroalkoxy (PFA).

These products are not only remarkable for their good UV resistance, physiological harmlessness and outstanding processability, but also for having the best chemical resistance and thermal stability of all thermoplastics.

PVDF can be used in an operating temperature range of –30°C to +140°C, ECTFE from –40°C to +150°C, PFA and FEP even cover the range from –190°C to +260°C .

These materials offer optimum conditions for the chemical, galvanic, electrical and semiconductor industries, medicine and nuclear technology, as well as energy and environment.

![24599-[Converti]](https://www.ctra.com.tn/wp-content/uploads/2021/11/24599-Converti.jpg)